RFID Applications in Circular Economy

With new regulations, the EU expects to decrease packaging waste by 15% before 2040 including mandatory reuse quotas for food and beverage packaging. European businesses face demands to create reuse methods at scale. RFID (Radio Frequency Identification) technology is surfacing as a method to keep track of cups and boxes that companies reuse. This leads to fewer lost items, lower expenses along with better rule-following. Remember, in the past reusable containers and bottles were once the norm in packaging. That is, until plastic was invented.

The size of today’s challenge

Single-use plastic creates overwhelming amounts of waste, as manufacturers produce more than 400 million tonnes each year. From this total 40% gets thrown away after one use. About 8 million tonnes of plastic end up in ocean waters annually, which harms sea creatures and their habitats. At the current rate of disposal, plastic materials in oceans will outweigh fish by 2050.

Single-use plastics create financial burdens plus risks to human wellness. Governments spend billions on waste management and cleanup, while microplastics infiltrate our food, water, and even the air we breathe. Society needs to switch from throwaway items to permanent containers without delay.

RFID in smart waste bins and recycling management

In Amsterdam and Barcelona, bins equipped with RFID technology record how people throw things away and help create better pickup routes that reduce pollution. The authorities in South Korea put RFID markers on food waste containers to make people pay according to how much food they discard, which leads them to throw away less.

Reusable packaging & reverse logistics

RFID technology continues to spread through packaging sectors, especially in product movement tracking. Large companies like CHEP and IFCO now put RFID tags on their returnable boxes and platforms, which helps get items back and prevents losses.

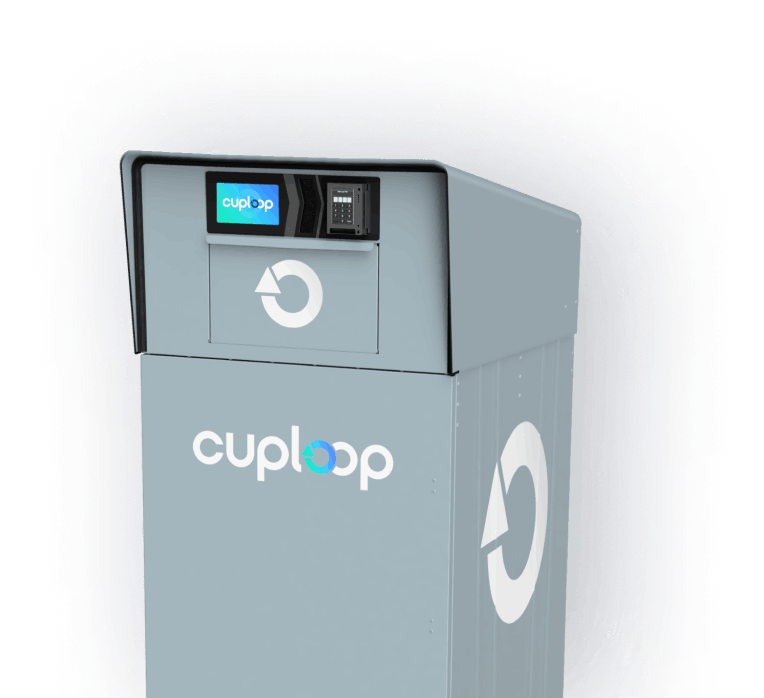

Reportedly, on Danish streets, machines with RFID readers get back 88 out of 100 cups. In British locations, Cuploop’s RFID enabled return kiosks receive 96 out of 100 cups – this beats manual collection methods by a large margin.

Return stations with RFID sensors accept containers, after which they are cleaned, and then put back into use, which cuts down on throwaway items. Such examples point out that better methods exist than single-use.

Product lifecycle management and extended producer responsibility (EPR)

RFID technology lets companies monitor their products from creation to disposal. For example Dell places RFID chips inside laptop parts to observe materials, which simplifies the collection and reuse of components during refurbishment. In response to the European Union’s EPR rules, industries such as battery producers now add tracking systems to meet recycling requirements and follow sustainability guidelines.

Textile and fashion industry

The fashion sector turns to RFID for extended product use and reduced waste. Through RFID-based digital tags in clothes, H&M and Zalando provide details about fabric content and washing methods, which leads to better resale and recycling processes. The second hand clothing market also benefits from this technology, as platforms like Trove use RFID to verify items and manage product counts in their rental and resale operations.

Food waste reduction and supply chain visibility

RFID technology helps retailers cut food waste through expiration date monitoring. The system notifies employees about products close to expiring, which cuts back waste in grocery stores. Walmart tracks shipment temperatures with RFID, keeping perishables at proper temperatures to prevent spoilage. Companies like Too Good To Go team up with markets to find and save extra food through RFID tracking.

Construction and materials reuse management

In construction, RFID brings sustainability through better material handling. The technology finds materials at quick speeds with precision between one to several meters. On its sites, Skanska tracks rented equipment through RFID to use resources better and cut extra production. The company reports that RFID gives them exact counts of people entering and leaving work areas with speed and precision.

What comes next

As RFID joins with IoT and blockchain systems, reuse programs become more precise and clear. This mix of technologies leads to better choices by leaders and more teamwork between package makers, stores, along with cities. Despite setup costs, technical integration hurdles, and data security needs, the benefits make it valuable. Through improved delivery systems, less waste along with better customer involvement, RFID advances the reuse of materials.

Conclusion

The transition from single-use to reusable packaging is an environmental, economic and social necessity. The use of RFID technology offers a route to reuse systems that are much more efficient, transparent, and scalable, fuelling Europe’s sustainability targets and contributing to a resilient and circular economy. As pilot initiatives develop and technology matures, RFID’s integration with complementary systems is likely to make it a cornerstone of sustainable packaging practices along the continent.

Would you like to discuss how Cuploop can integrate into your business? Book a quick demo with Kristi!